The RedHV+ project requires the study of a large number of aspects which follow on from conventional gearboxes and which are related to the particularity of the high speed input into the gearbox. These points may be grouped into six separate areas.

Certain technological obstacles will have to be overcome in order to guarantee a successful outcome to the project. These obstacles relate on the one hand to the high-speed issue and on the other hand to the automotive application. In addition to the cost of series production which must be low, there are many constraints connected to stress cycling and service life. One or more obstacles correspond to each of the previously identified areas.

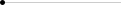

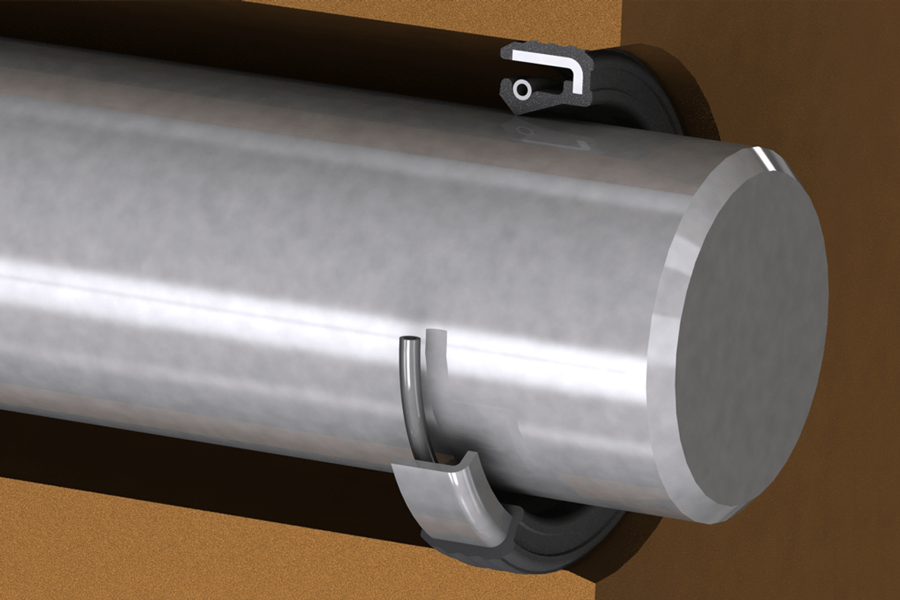

Bearings

Aspects

- Study of the mechanical behaviours and the lubricant related to the high speed.

- Use of bearings with new coatings or even ceramic hybrid bearings in an automotive application

- Production of a model to calculate the losses related to the reliable bearing in the field of high speeds.

Obstacles

- Ensure lubrication and service life

- Limit and evacuate heat

- Limit centrifugal effects

- Minimise the drag torque

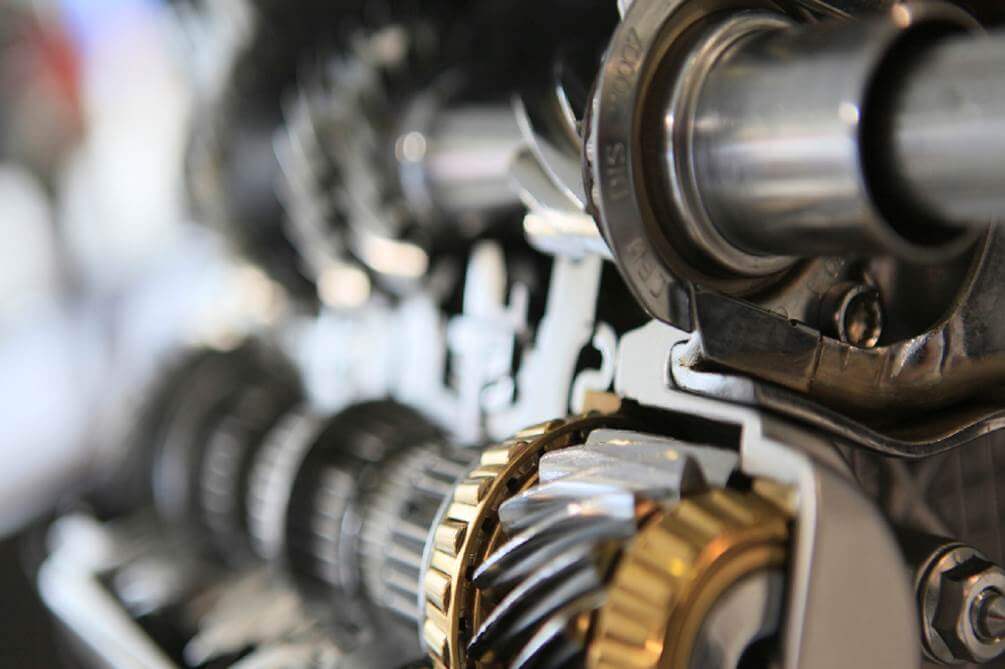

Gears

Aspects

- Development of new heat treatment and surface coating applications to comply with specifications in terms of performance, efficiency and durability.

- Compare various material solutions

- Study and optimisation of the efficiency of high-speed teeth

Obstacles

- Withstand stress cycling

- Provide proper efficiency

- High torque starting (problem compared with low torques during normal rating and high-speed).

Lubrication

Aspects

- Study high-speed splashing and progress on the topic of oil airing

- Development of a model to predict the power losses related to splash lubrication and optimising these losses,

- Proposed alternative if splashing reaches its limits

Obstacles

- Offer proper lubrication of all components without deteriorating efficiency.

- Control the evacuation of heat on a gearbox with very high transmitted power/weight ratio.

- Work in close cooperation with a lubricant manufacturer in order to control the properties of the fluid which have real impact on ventilation and accordingly develop an oil that limits losses by splashing.

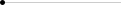

Sealing

Aspects

- Use of seals on shafts rotating at high-speed in an automotive environment.

Obstacles

- Decrease to a maximum, the power losses related to the seals on the high-speed portion.

- Solve the problems of hardening and deterioration of the lips by the thermal effects related to friction.

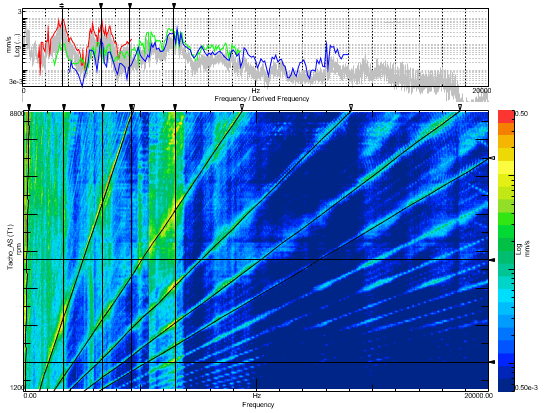

Dynamics & Acoustics

Aspects

- Study on the dynamics of high-speed teeth and on the engine shaft.

- Implementation of solutions which are rarely or not at all used in motor vehicles to reduce the level of extraction of the gearbox.

Obstacles

- Reduce the acoustic impact of the gearbox to a minimum.

- Limit and control the generation of high frequency vibrations which cause high coupling between the moving components and the structures.

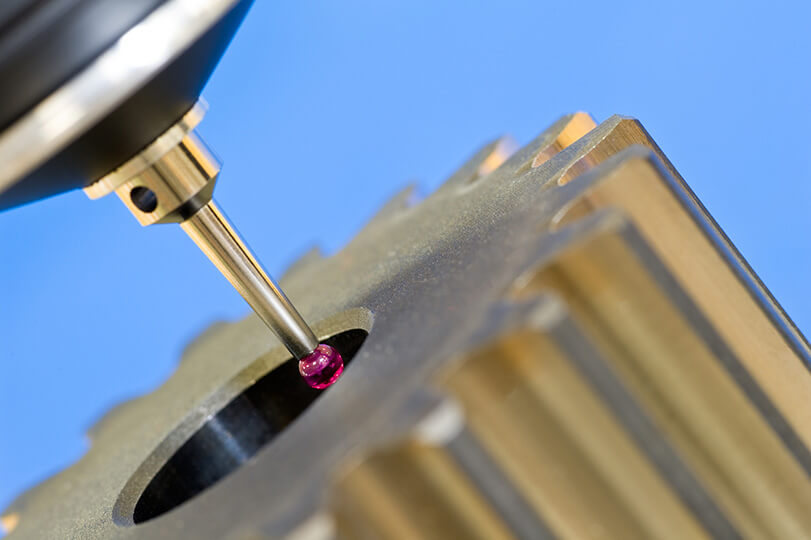

Machining

Aspects

- Search for an innovative design to reduce the cost of the complete gearbox.

- Study of cost effective gear manufacturing methods.

Obstacles

- Comply with the requirement of accuracy related to the high-speed, at automobile cost.